Suspension Design and Fabrication

As a member of the suspension subteam on my collegiate FSAE team, I learned a lot of technical skills in addition to leadership, organizational, and collaboration skills.

For the 2021-2022 academic year, I worked on learning about vehicle dynamics, understanding the previous state of the car when the previous

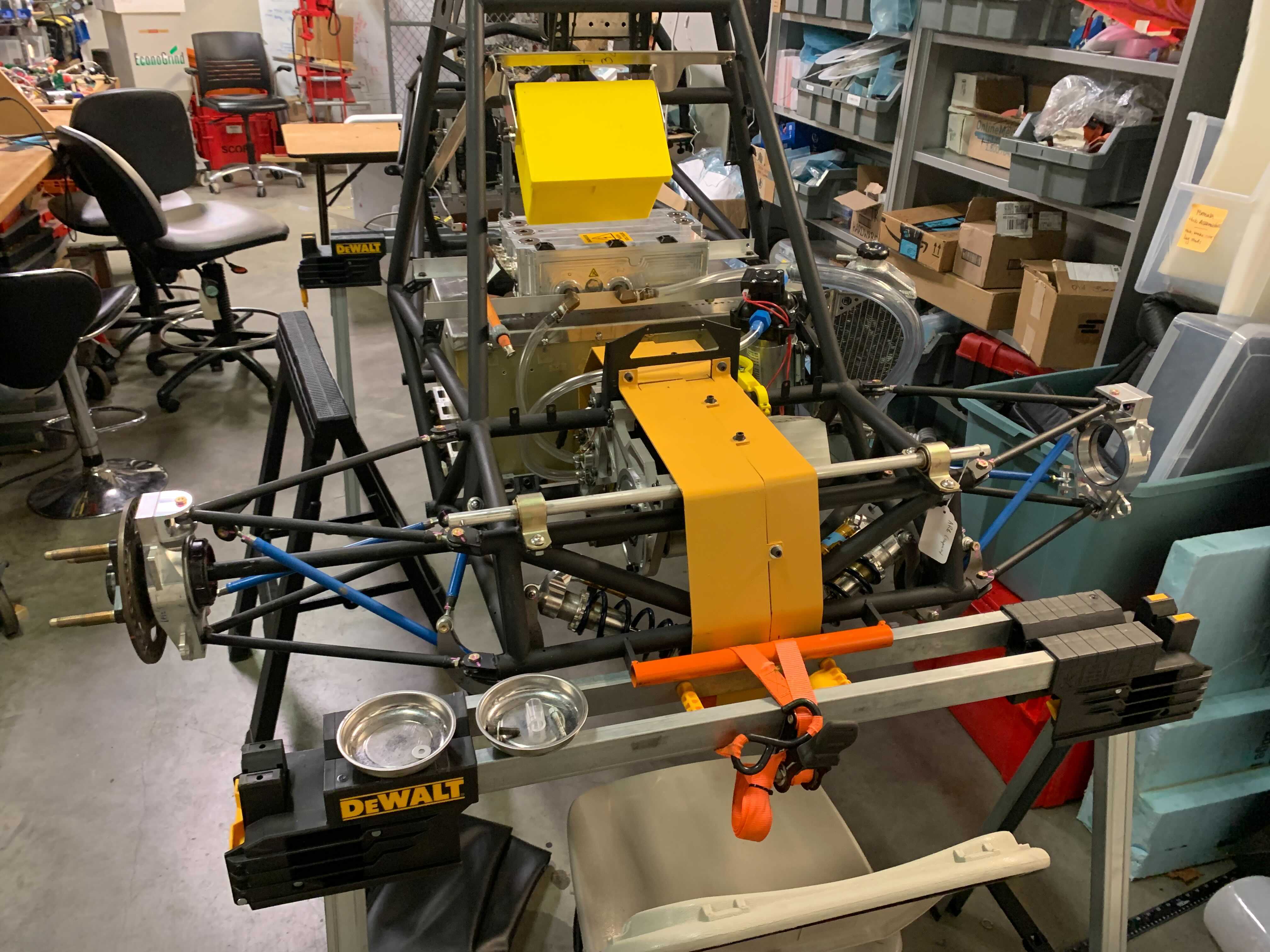

team members had to leave for COVID, and compiling the information on what needs to be made and parts already fabricated. I designed and fabricated parts for the suspension system and worked to assemble the system as a whole, ensuring everything was compliant with the FSAE rules. I created and taught lessons on vehicle dynamics and suspension design for the new first-years.

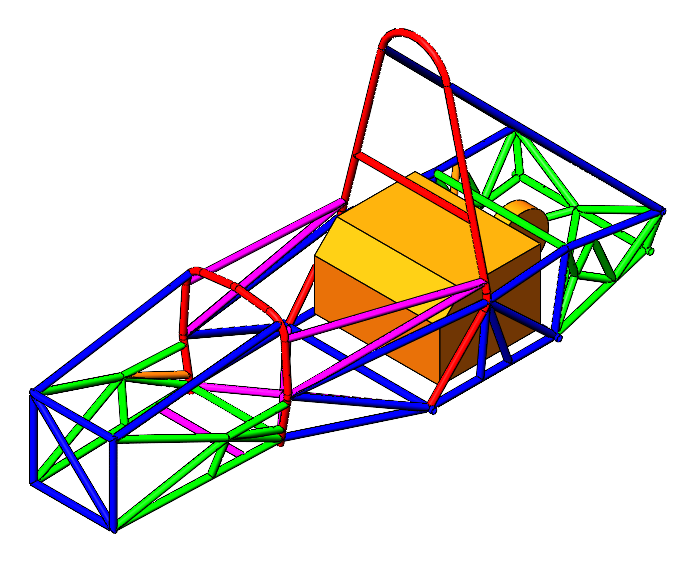

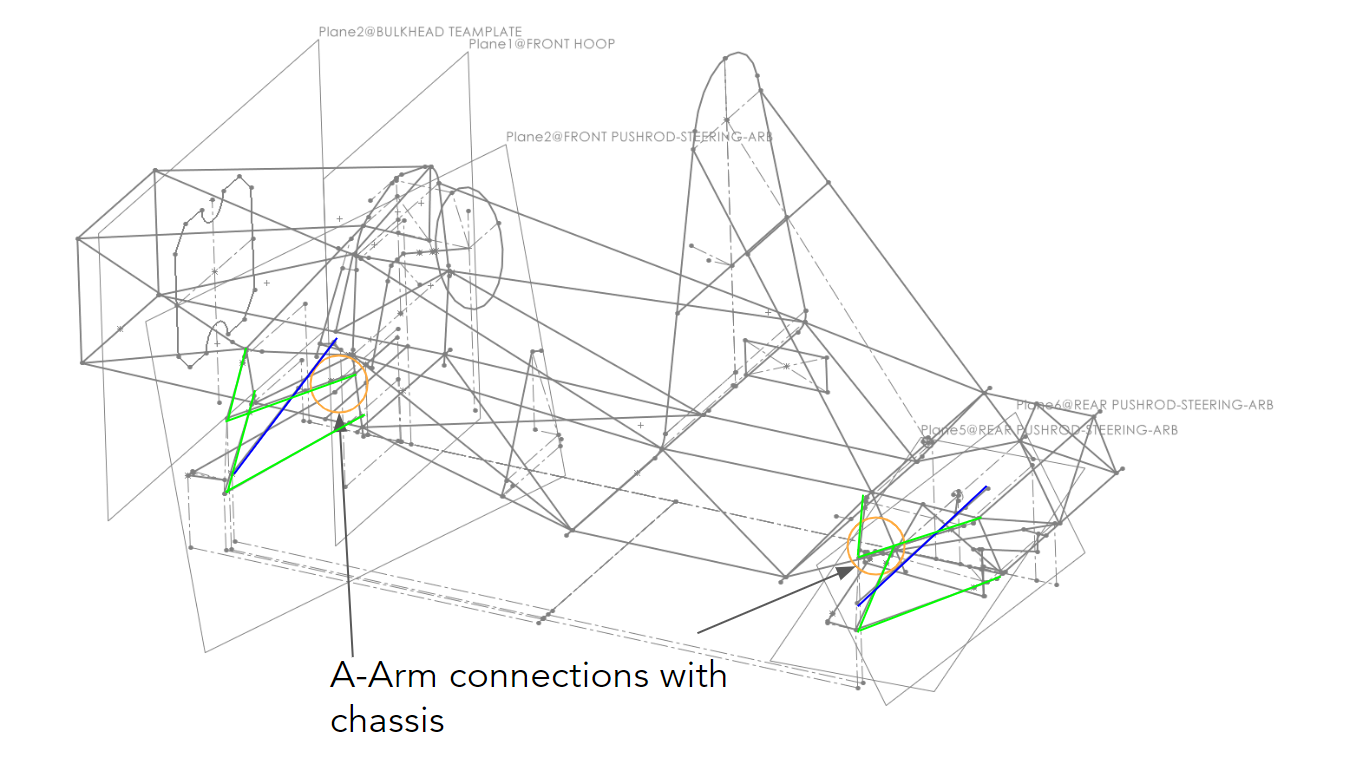

For the 2022-2023 academic year, I helped design the current suspension system using a MATLAB script to determine suspension nodes that implements gradient optimization to find possible nodes within a specified solution space based on high-level suspension characteristics.

I have also been mentoring the current suspension lead, offering help and guidance whenever they need it.

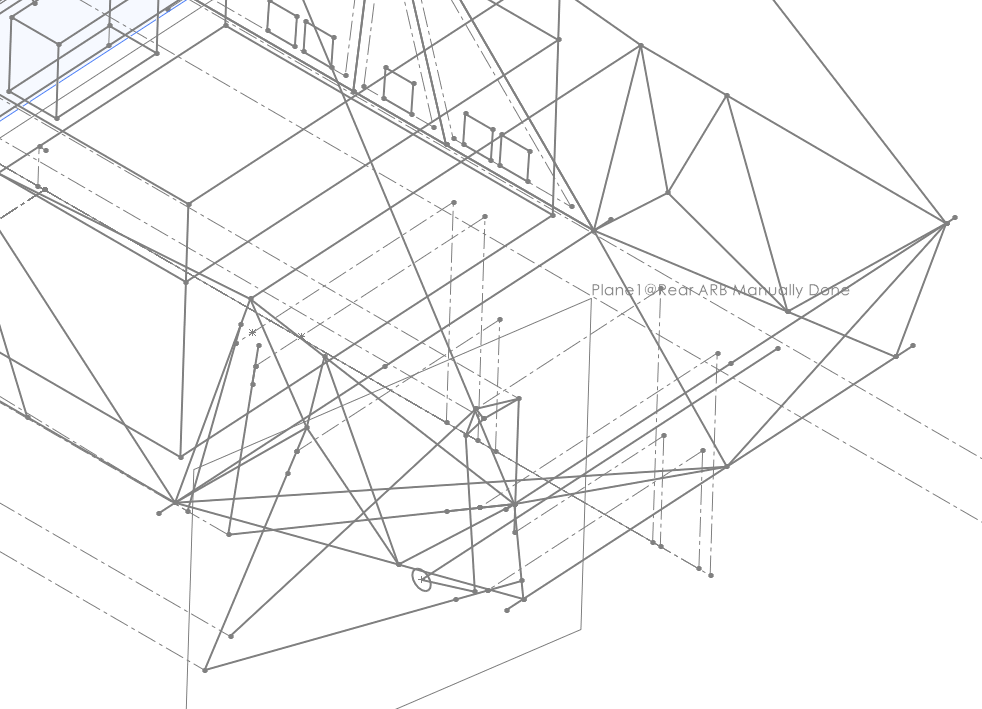

To complete suspension design, we had to take the nodes outputted from MATLAB and enter them into SolidWorks, ensuring there are no interferences between suspension members and that the geometry makes sense.

I have also worked on making tabs, jigs, and conducting FEA - ensuring a proper factor of safety, manufacturability, and sufficient tooling space.

Our slideshow showcases our team’s overall design process, and slides 19-33 focus on our suspension design, fabrication, assembly, and testing.